Precision/Investment/Lost Wax Casting ANSI Centrifugal Pump Impeller for Oil Paper Chemical Industry

Basic Info.

| Model NO. | ANSI ZLT196 Pump Parts |

| Port of Loading | Qingdao |

| Item | Pump Impeller |

| Pump | ANSI Pump |

| Referece | 2D/3D, 100% as Per Drawings |

| Inspection | Hardness Tester, Roughness Tester, Caliper etc |

| Material for | 316ss, CD4, 304SSS,Titanium, Carbon Steel etc. |

| Certificate | Bureau Veritas |

| Surface Treatment | Blacking, Polishing, Anodize, Chrome Plating, etc |

| Name | ANSI Zlt 196 Centrifugal Pump Parts |

| Transport Package | According to The Customers′ Requirement |

| Specification | according to the drawings |

| Trademark | ZLT |

| Origin | Zibo, Shandong Province, China |

| HS Code | 84139100 |

| Production Capacity | 5000 Tons Per Year |

Packaging & Delivery

Package Size 50.00cm * 40.00cm * 30.00cm Package Gross Weight 10.000kgProduct Description

Company Profle:

1. Our factory Zibo Qingdong Machinery Manufacturing Co., Ltd has been verified by the French Bureau Veritas of ISO9001:2008 quality system certification, whose export department Zibo ZLT International Trade Co., Ltd is graded as TOP A company in Chinese Customs Classification Management which means the hightest reputation and trustful company.2. Our factory devotes to lost wax casting, sand casting and lost foam casting for many years. Our products include counter weight iron, pump parts, diffuser, mining equipment spare parts(such as shaft), and they are exported to the USA, Canada, Sweden, Israel, Hungary, Guyana, Mexico, South Korea, Indonesia, etc and win the high reputation.3.Our annual output is more than nine millions USD.

Product Description:

| Product Name | Precision/Investment/Lost Wax Casting ANSI Chemical Process ZLT 196 Centrifugal Pump Impeller Pump Parts Used in Oil Paper Chemical Industry |

| Material | Stainless Steel, Carbon Steel, Alloy Steel,etc. |

| Material Grade | GB, ASTM, AISI, DIN, BS, JIS, NF |

| Process | CNC Machining, Auto Lathe Machining, Meter Lathe Machining, Wire Cutting, EDM Cutting, Gringding, Milling, Drilling, Screwing, Cutting, Stamping |

| Tolerance | CT-9+/-0.005mm |

| Surface treatment | Blacking, Polishing, anodize, Chrome Plating, Zinc Plating, Nickel Plating or other as requirements. |

| Inspection | 3D Coordinator, Hardness tester, Roughness tester, Caliper etc. |

| Company Certificate | GB/T 19001-2008,ISO 9001:2008; BV;Graded as TOP A company in Chinese Customs Classification Management which means the highest reputation and trustful company for exporting. |

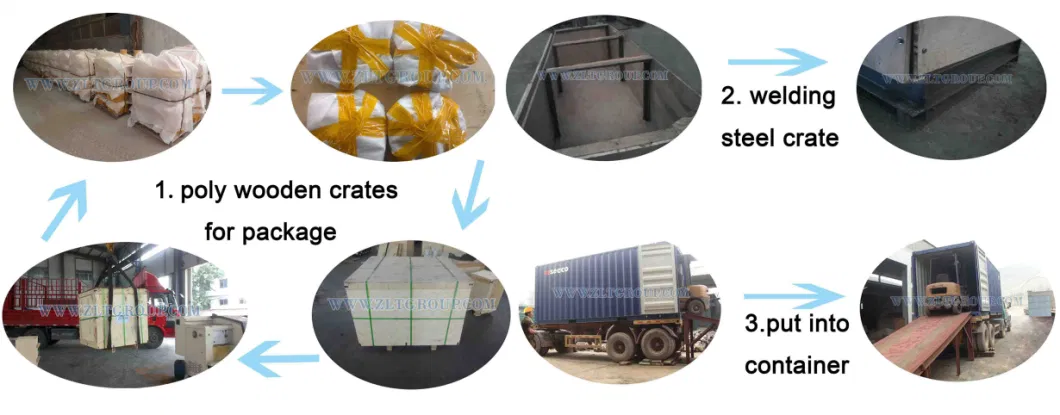

Packing | 1. Small part, single packed then put into paper carton then to crate.2. Poly wooden crates suitable for shipping on the sea.3. Welding steel crate. The size and steel thickness is according to the product dimension and weight.4. We also consider customers' special needs for packing. |

Delivery | 30days after receiving the deposit |

| Payment | 50%TT in advance and the balance is paid against the copy of B/L. |

Manufacture Craft:

| Caft | Clarify | Process | Material |

| Lost Wax Casting | silicon colloidal | moulding | Stainless steel, carbon steel, titanium alloy, high chrome, cast iron, bronze, ductile iron brass, etc. |

| pouring | |||

| waterglass bonded | machining | ||

| testing | |||

| Sand Casting | resin sand craft | moulding | Stainless steel, carbon steel, titanium alloy, high chrome, cast iron, bronze, ductile iron brass, etc. |

| pouring | |||

| silicate bonded sand craft | machining | ||

| testing | |||

| composite shell | |||

| Lost Foam Casting | moulding | Stainless steel, carbon steel, titanium alloy, high chrome, cast iron, bronze, ductile iron brass, etc. | |

| pouring | |||

| machining | |||

| testing |

Manufacture Process Pictures:

Equipment and Testing:

Certificate:

Exhibition:

Packing Methods:

| Packing Methods | |||||||||

| Small part, single packed then put into paper carton then to crate. | |||||||||

| 1. Generally use poly wooden crates for package. | |||||||||

| Minimum poly wooden board thickness: 20mm | |||||||||

| Steel band: 19× 0.5mm or 15× 0.5mm | |||||||||

| Common crate size is less than 1200X1000X1000mm | |||||||||

| 2. For the very big part, use welding steel crate. The size and steel thickness is according to the product dimension and weight. | |||||||||

| 3. Large size and large quantity part, put into container directly. | |||||||||

| 4. We also consider customers' special needs for packing |

FAQ

1.Are you a factory or a trading company?

Zibo Qingdong Machinery Manufacturing Co., Ltd. is a professional factory of pump parts, ANSI ZLT 196 and ZLT Mark III pump parts, centrifugal pump parts, submersible pump parts, mining equipments and machinery parts etc.

2.Can I be your agent?

Yes, welcome to deep cooperation.

3.How do I know the quality is up to the OEM standards?/What's your quality guarantee?

OEM is available. We have passed the ISO 9001-2015 and BV certificate, and we have been cooperating with many companies in America, our products have passed their test. Or you can test our products by trial order. We have our own mould and drawing for the ANSI ZLT 196 and ZLT Mark III pump parts.

4.Is the sample available?

Yes, samples are available for you to test the quality.

5.Are the products tested before shipping?

Yes, all of our products were qualified by Spectrameter, Hardness Tester, Toughness Tester, Dynamic Balancing Tester, PT Tester, Hydro Test before shipping.

6.How we cooperate?We will quote you the price according to your drawing and 3D drawing or the samples.